Brewing Process

M

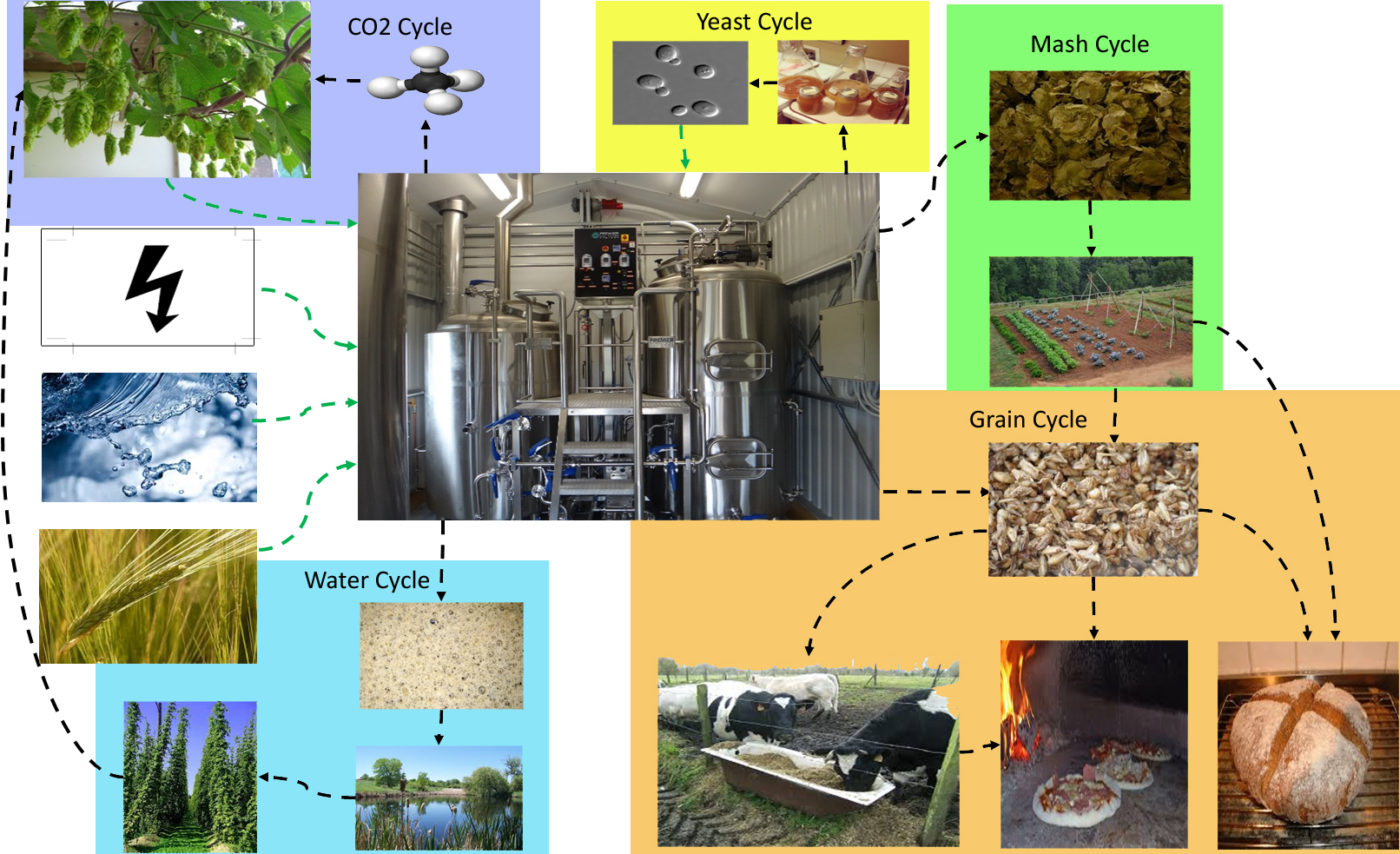

Here at GodsOwn Brewery we have considered the environmental impacts of operation and developed a strategy to minimize them.

There are 4 main ingredients that make beer. These are water, malt, yeast and hops. Our water comes from a bore on our property plus we have added a 4000L rain water tank. The bore water has a good level of calcium bi-carbonates (hard water) for darker beer styles but it can be mixed with the rain water to produce lighter styles of beer. The water that is unable to be recycled back into the system becomes waste water which is pumped out to our reservoir. This water is then used to irrigate our hop field and paddocks.

We have trialled hop growing here since 2011. As this went so well we have started our own hop farm. We aim to grow some hop varieties not currently available in New Zealand. Hops are added at different stages of the brewing process depending on the result the brewer is after. They are then removed and can be composted.

Different yeast strains work for different styles of beer. After the yeast has done its work fermenting the beer it is drained off and can be re-pitched and used again. What doesn’t get re-used can be put on the garden as compost.

We buy in our malt. After it has been crushed and mashed to produce the wort its job is done. What is left over is a wet grain which is perfect for adding to bread and pizza bases. This ‘spent’ grain is also a nutritious animal feed.

We have future plans to grow and experiment on a small scale for making our own malts.

Obviously energy is also required to make this all happen. We use electricity, LPG and CO2 to carbonate the beer. There are associated emissions from the process. Here at Godsown Brewery we have planted over a hundred trees already and will be planting Olive and Manuka trees to use in our pizza oven. We aim to be carbon neutral.